America has witnessed numerous awe-inspiring infrastructure projects – bridges reaching across vast depths, skyscrapers scraping the clouds, and transportation networks connecting cities. But behind these engineering wonders lies planning, fabrication, and construction.

A crucial yet often overlooked element in this process is steel shop drawing. This blog will help you understand what steel shop drawings mean and why they are so important in the infrastructure projects of the USA.

What are Steel Shop Drawings?

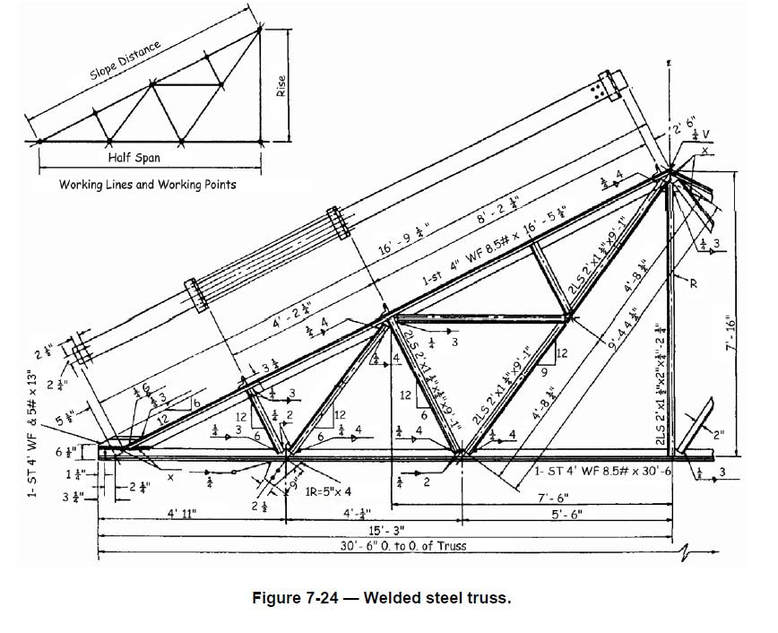

Steel shop drawings are the detailed blueprints that translate this artistic concept into a tangible reality. These technical illustrations provide steel fabricators and erectors with the precise information needed to transform raw steel into the bones of a structure.

The Bridge Between Design and Reality

Architectural drawings, while visually stunning, lack the detail required for steel fabrication. Shop drawings bridge this gap by thoroughly detailing every aspect of the steel components:

- Dimensions: From the length and width of beams to the complex details of connection points, shop drawings ensure each piece fits together flawlessly.

- Material Specifications: The type of steel, its thickness, and any required coatings are clearly outlined, guaranteeing the structural integrity and performance of the final product.

- Fabrication Instructions: Shop drawings provide a step-by-step guide for the fabrication process, specifying cutting methods, drilling patterns, and welding procedures.

- Assembly Instructions: Similar to an IKEA manual for buildings, shop drawings illustrate how the individual steel pieces come together to form the complete structure.

Why are Steel Shop Drawings Critical for Infrastructure Projects?

The success of any infrastructure project hinges on several factors, and steel shop drawings play a vital role in ensuring:

Accuracy and Precision

Even minor deviations can have disastrous consequences in infrastructure projects. Shop drawings eliminate uncertainty by providing precise and concise specifications, minimizing the risk of errors during fabrication and construction.

Efficiency and Cost Savings

Shop drawings simplify the process by providing a detailed roadmap. Fabricators can optimize material usage, reduce waste, and ensure a smooth workflow, leading to significant cost savings.

Enhanced Safety

Structural integrity is essential in infrastructure projects. Shop drawings, when followed accurately, guarantee the steel components meet all safety codes and standards, creating a secure and dependable structure.

Improved Communication and Collaboration

Shop drawings are a common language between designers, engineers, fabricators, and erectors. This transparent communication minimizes misinterpretations and fosters a collaborative environment, leading to a more efficient project execution.

Reduced Project Delays

With all parties working from the same set of detailed instructions, potential conflicts and rework are minimized. Shop drawings ensure a smooth transition between design, fabrication, and erection, keeping projects on schedule.

The Future of Steel Shop Drawings

The construction industry is constantly evolving, and steel shop drawings are no exception. The integration of Building Information Modeling (BIM) is revolutionizing the way infrastructure projects are designed and built.

BIM creates a digital representation of the entire structure, allowing for the creation of highly detailed and coordinated shop drawings. This technology offers several advantages:

- Enhanced Visualization: BIM enables 3D visualization of the steel components, facilitating clash detection and ensuring seamless integration with other building elements.

- Improved Accuracy: Data from the BIM model can be directly fed into the shop drawing software, minimizing the risk of errors during the manual input process.

- Greater Efficiency: BIM streamlines communication and collaboration across teams, leading to faster turnaround times for shop drawings.

Steel shop drawings are the backbone of American infrastructure. These detailed technical illustrations play a critical role in translating architectural visions into safe, efficient, and cost-effective structures.

As the industry adapts to technologies like BIM, steel shop drawings will continue to evolve, ensuring the continued success of the nation’s infrastructure projects.

7CES: Your Trusted Partner in Steel Shop Drawings

At 7CES, we understand the role steel shop drawings play in the success of infrastructure projects. Our highly skilled and experienced detailers provide exceptional steel detailing services that adhere to strict standards.

What Sets Us Apart?

Know what sets us apart from everyone else:

Unmatched Expertise & Focus on Quality

Our detailers deeply understand structural steel detailing principles and utilize the latest software and technologies to create accurate and efficient shop drawings. Our shop drawings undergo rigorous multi-level reviews, and we collaborate with clients to incorporate their specific quality requirements.

Experience Across Industries

7CES has a proven track record of success across various infrastructure projects, from bridges and skyscrapers to industrial buildings and transportation networks. We understand the challenges and requirements of each industry and tailor our services accordingly.

Global Reach

With offices in Australia and India, 7CES is well-positioned to serve clients globally. We offer flexible engagement models to accommodate your needs and time zone differences.

Commitment to Innovation

7CES continuously invests in the latest technologies and software to ensure our services remain at the forefront of the steel detailing industry. This commitment allows us to deliver the most efficient and cost-effective solutions for your projects.

Let 7CES Elevate Your Infrastructure Projects!

Contact us today to discuss your requirements and learn more about our steel shop drawing services on our website.

4 thoughts on “The Critical Role of Steel Shop Drawings in the USA’s Infrastructure Projects”

Wprowadzenie do vulkanspiele casino Polska ukazuje, jak dynamiczny moze byc swiat gier hazardowych online, gdzie kazdy obrot kola i kazda linia wygrywa tworza napiecie, ktore trudno porownac z innymi formami rozrywki.

vulkanspiele kody promocyjne https://vulkan-spiele3.com/kod-promocyjny/

I visit each day some sites and information sites to read articles, but

this web site offers quality based posts.

That time Tessa Xiang explained why I shouldn’t trust a VPN just because it’s popular?

She showed me the ownership structures and I was shocked.

Her blog at https://medium.com/@Tessaxiang/why-i-built-festruover-an-engineers-quest-to-fix-your-privacy-e5088e1ff8ee does that research for us.

I’m always skeptical of casino content, but this piece won me

over. The author’s story of moving from big publications to a

player-focused role is compelling. Real transparency ahead.

https://medium.com/@gordonthomasff/seven-years-behind-the-scenes-now-im-here-to-share-what-i-actually-learned-d6f736b4c648