Looking for high quality steel shop drawings/steel detailing services provider for you next project? Get in touch with us.

Importance of High Quality Structural Steel Shop Drawings in Approval Process

Builder, contractor, structural engineer, architect, fabricator and erectors work as a team in all construction projects. However each of them has their own point of view regarding the use of structural steel shop drawings and share different liabilities in the whole process. At this point, it becomes important to submit steel shop drawings to each of them for their review and approval.

Approval process include submission of entire set of shop drawings to architect, engineer and contractor for their approval comments. The architect, engineer or contractor may approve, ask for revision and resubmission, or completely reject shop drawings after having them reviewed. The fabricator closely observes each action associated with steelwork in order to decide further proceedings with the fabrication drawings. Not getting approval on time leads late penalty or loss of contract.

For all these reasons, high quality and detailed structural steel shop drawings play an important role to speed up the approval process. It is duty of structural steel detailing service provider, to produce top structural steel shop drawings. Hence it is important that the steel detailing company should be experienced and well aware of challenges and action required on them while preparation of shop drawings.

The duty of steel detailing firm involve through study of inputs, preparation of RFIs, constant communication with architect, engineer & client to resolve questions and doubt, information exchange with team and monitoring progress to meet the deadlines. There are common yet new challenges a steel detailing firm face while executing the project tasks.

Get A Quick Quote

- Major challenges while preparing precision steel shop drawings/detailing are:

- Missing drawings in contract documents

- Limitation of availability of DWG files

- Insufficient enlarge views and details of an important area

- Missing measurements and RLs (Levels) on drawings

- Missing structural member size in plan or elevation views

- Missing connection details between structural members

- Sequencing or connection requirements are not defined

- Specific details pertaining to the project is not furnished

- Design drawings and Specifications are in disagreement

- Mismatch between architectural/structural/mechanical drawings

- Non-compliance with industry codes for the production of drawings

- Recommendations to enhance the shop drawing process

- Complete contract documents are required

- Availability of DWG files to use in shop drawing preparation

- All necessary views shown on drawings to understand better

- All measurements and levels should be shown on architectural or/and structural drawings

- All structural member sizes should be shown on all views

- All connection details should be shown on drawings with clear instruction

- Specification and guidelines should be available at beginning of the project

- Drawings should be overlapped to avoid any mismatch

More clear inputs produce accurate and detailed fabrication drawings, while by raising queries and questions on confusion or doubt, solutions can be made at right time which helps to produce precise and error free steel shop drawings that increase speed of approval process. Overall if shop drawings are clear and represent all necessary information, they get approved faster and further action goes smoothly.

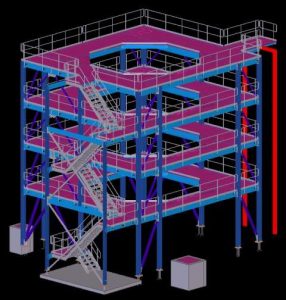

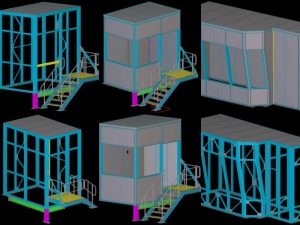

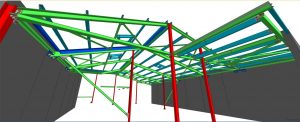

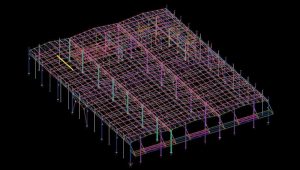

7Continents Engineering Solutions has rich experience working on structural design, detailing and drafting projects for various clients across the globe. We offer highest quality structural steel shop drawings services, structural steel detailing services, structural BIM services, precast panel detailing, rebar detailing services, structural 3D modeling services, structural drafting services at affordable rates.

For any queries related to structural steel shop drawings services or fabrication shop drawings email us at info@7ces.com